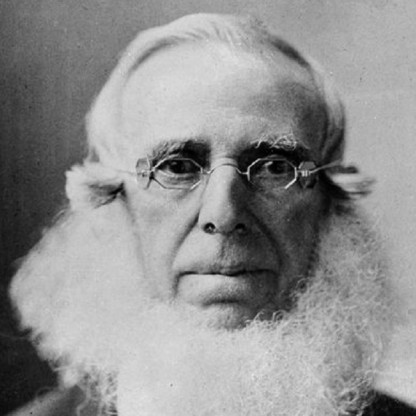

Bessemer's father, Anthony, was born in London, but moved to Paris when he was 21 years old. He was an Inventor who, while engaged by the Paris Mint, made a machine for making medallions that could produce steel dies from a larger model. He became a member of the French Academy of Science, for his improvements to the optical microscope when he was 26. He was forced to leave Paris by the French Revolution, and returned to Britain. There he invented a process for making gold chains, which was successful, and enabled him to buy a small estate in the village of Charlton, near Hitchin in Hertfordshire, where Henry was born. He married Samantha Grace Delton in 1862.